In the world of plumbing, there are two main types of systems: open and closed. While open systems are relatively straightforward, allowing air to freely enter and exit the pipes, closed plumbing systems are a more complex and specialized design. Understanding the intricacies of a closed plumbing system is crucial for homeowners, builders, and plumbing professionals alike, as it impacts the functionality, efficiency, and safety of the entire plumbing network.

Table of Contents

ToggleDefinition and Purpose

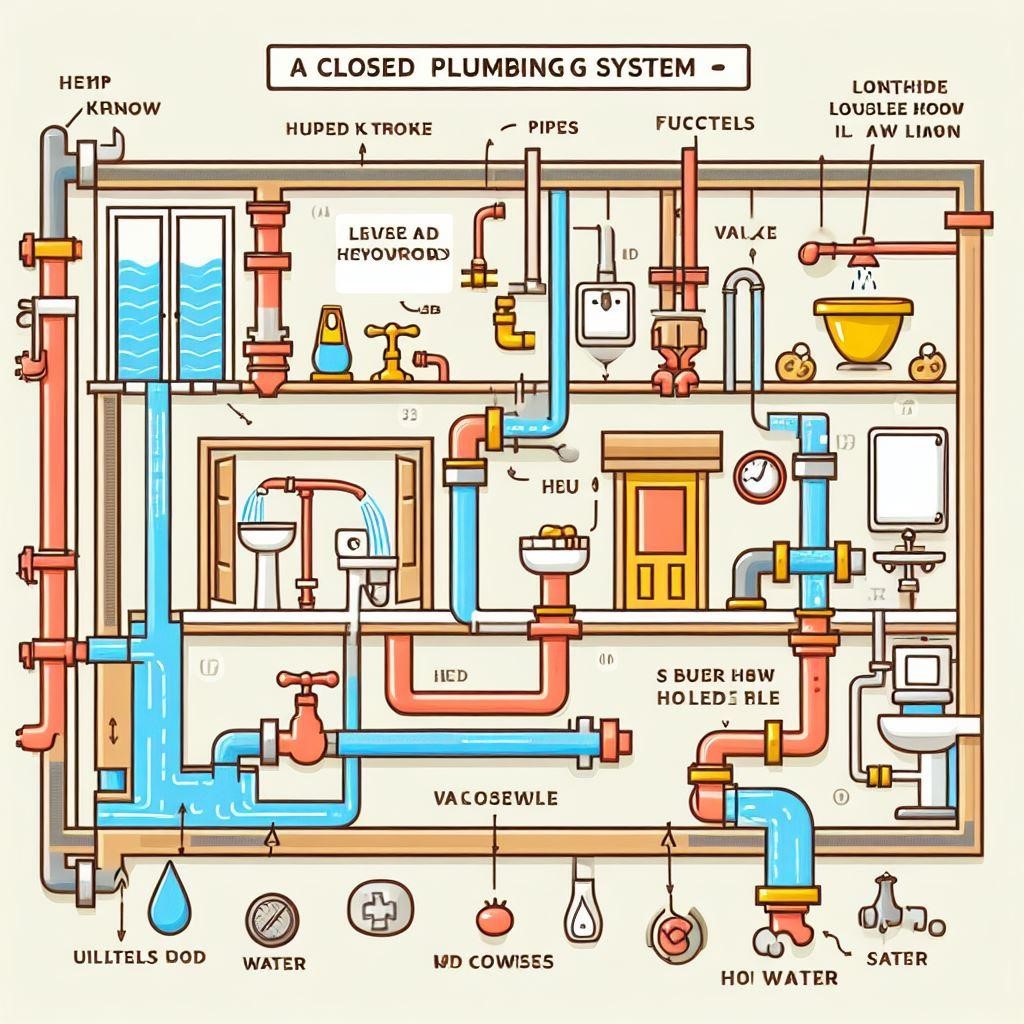

A closed plumbing system, also known as a sealed or pressurized system, is a type of plumbing installation where the pipes and fixtures are designed to operate under constant pressure. Unlike open systems, which rely on atmospheric pressure, closed systems use a variety of components and techniques to maintain a specific level of pressure within the pipes. The primary purpose of a closed system is to ensure a consistent flow of water throughout the plumbing network, even when multiple fixtures are in use simultaneously.

Components of a Closed Plumbing System

To function effectively, closed plumbing systems require several essential components:

- Pressure Vessel: Also known as an expansion tank or compression tank, this component is designed to accommodate the expansion and contraction of water as it heats and cools within the system. It helps maintain a consistent pressure by providing a cushion of air or inert gas, preventing the pipes from becoming over-pressurized or experiencing a vacuum.

- Pressure Relief Valve: This safety device is installed to prevent excessive pressure buildup within the system. If the pressure exceeds a predetermined threshold, the relief valve opens to release the excess pressure, protecting the pipes and fixtures from potential damage or failure.

- Air Eliminator: As its name suggests, an air eliminator is designed to remove any air that may become trapped within the closed system. Air can accumulate over time and interfere with the efficient flow of water, causing noise, reduced pressure, and potential damage to system components.

- Backflow Prevention Devices: Closed plumbing systems require backflow preventers to ensure that water flows in the intended direction and does not allow contaminants or non-potable water to enter the system. These devices are installed at strategic points, such as the water meter or fixtures, to maintain the integrity of the potable water supply.

- Circulating Pump: In certain closed systems, such as those used for hydronic heating or hot water recirculation, a circulating pump is employed to continuously move water through the system, ensuring a steady supply of hot water at each fixture.

Applications of Closed Plumbing Systems

Closed plumbing systems are commonly found in various residential, commercial, and industrial applications, including:

- High-Rise Buildings: In tall buildings, closed systems are essential for delivering water to upper floors with sufficient pressure, overcoming the effects of gravity and friction loss in long vertical runs of piping.

- Hydronic Heating Systems: These systems use a closed loop of pipes to circulate heated water or a water-glycol mixture throughout a building, providing efficient and consistent heating.

- Hot Water Recirculation Systems: By continuously circulating hot water through a closed loop, these systems ensure that hot water is readily available at each fixture, reducing water waste and improving energy efficiency.

- Process Piping Systems: Many industrial processes, such as chemical plants, pharmaceutical facilities, and food and beverage operations, rely on closed plumbing systems to maintain precise control over fluid flow, temperature, and pressure.

- Radiant Heating and Cooling Systems: In these energy-efficient systems, a network of closed loops embedded in floors, walls, or ceilings circulates heated or chilled water to provide comfortable and evenly distributed heating or cooling.

Advantages of Closed Plumbing Systems

Closed plumbing systems offer several advantages over traditional open systems:

- Increased Water Pressure: By maintaining a consistent level of pressure within the pipes, closed systems ensure a strong and reliable water flow, even when multiple fixtures are in use simultaneously.

- Energy Efficiency: Closed systems, particularly those used for hot water recirculation or hydronic heating, can significantly reduce energy consumption by minimizing heat loss and water waste.

- Enhanced Control: With the ability to precisely regulate pressure, temperature, and flow rates, closed systems offer greater control over the plumbing network, making them ideal for applications that require strict parameters.

- Reduced Noise: The absence of air pockets and the consistent pressure within closed systems can lead to quieter operation, reducing the likelihood of water hammer or other noise-related issues.

- Improved Water Quality: By preventing the introduction of contaminants and maintaining a sealed environment, closed systems can help preserve the quality of potable water throughout the distribution network.

Challenges and Maintenance Considerations

While closed plumbing systems offer numerous advantages, they also present unique challenges and maintenance requirements:

- Initial Cost: The installation of a closed system, with its specialized components and complex design, tends to be more expensive than a traditional open system.

- Maintenance and Repair: Due to the pressurized nature of closed systems, maintenance and repair tasks can be more complex and may require specialized knowledge and tools.

- Air Removal and Purging: Over time, air can accumulate within closed systems, necessitating periodic purging or the use of air elimination devices to maintain optimal performance.

- Expansion and Contraction: The expansion and contraction of water due to temperature changes must be carefully managed through the use of pressure vessels or expansion tanks to prevent damage to the system.

- Leak Detection and Repair: Identifying and repairing leaks in a closed system can be more challenging, as the pressurized environment may cause water to travel farther from the source of the leak, making it harder to pinpoint the exact location.

Professional Installation and Maintenance

Given the complexities involved in designing, installing, and maintaining closed plumbing systems, it is crucial to work with qualified and experienced plumbing professionals. These experts have the necessary knowledge and skills to ensure that the system is properly sized, configured, and installed according to local building codes and industry standards. Regular maintenance and inspections by certified professionals can help identify potential issues before they escalate, prolonging the lifespan of the system and ensuring its efficient and safe operation.

In conclusion, closed plumbing systems are a specialized and highly effective solution for various residential, commercial, and industrial applications. While they offer numerous advantages, such as increased water pressure, energy efficiency, and enhanced control, they also require careful design, installation, and maintenance. By understanding the components, applications, and unique considerations of closed plumbing systems, homeowners and professionals alike can make informed decisions and ensure the optimal performance and longevity of these intricate plumbing networks.