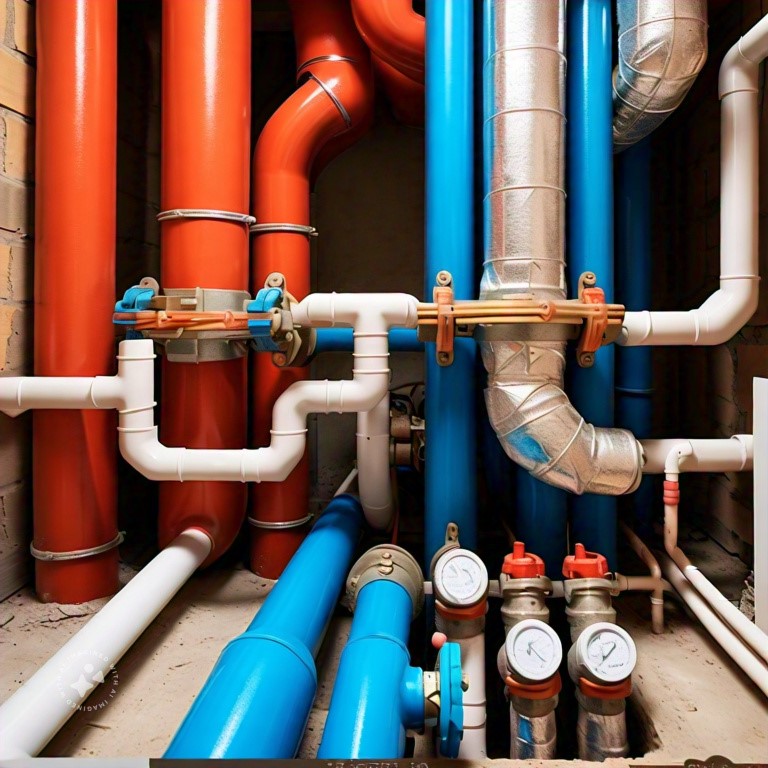

Heating systems are essential for maintaining comfort and safety in residential, commercial, and industrial buildings. A critical component of these systems is the heating pipework, which is responsible for transporting heated water or steam from the boiler to radiators, underfloor heating systems, or other heat emitters. There are various types of heating pipework, each with its own unique characteristics, applications, and benefits. This article explores the different types of heating pipework, their uses, and their advantages and disadvantages, providing a comprehensive guide to help you make informed decisions for your heating system.

Table of Contents

ToggleTypes of Heating Pipework

- Copper Pipework

- Steel Pipework

- Plastic Pipework

- PEX (Cross-Linked Polyethylene) Pipework

- CPVC (Chlorinated Polyvinyl Chloride) Pipework

- Stainless Steel Pipework

- Aluminium Pipework

1. Copper Pipework

Description: Copper pipework has been a standard in heating systems for many years due to its excellent thermal conductivity, durability, and reliability. Copper pipes are available in various sizes and thicknesses to suit different applications.

Applications:

- Central heating systems

- Hot and cold water distribution

- Underfloor heating systems

Advantages:

- Excellent thermal conductivity, ensuring efficient heat transfer.

- Durable and resistant to corrosion.

- High-pressure tolerance.

- Long lifespan, often exceeding 50 years.

Disadvantages:

- Higher cost compared to some other materials.

- Can be difficult to install due to its rigidity.

- Susceptible to theft due to its high scrap value.

2. Steel Pipework

Description: Steel pipework, particularly black steel and galvanized steel, is commonly used in larger heating systems, such as in commercial and industrial applications. It is known for its strength and ability to withstand high pressures and temperatures.

Applications:

- Large-scale heating systems in commercial buildings

- Industrial heating applications

- Boiler connections and distribution mains

Advantages:

- Strong and durable, suitable for high-pressure applications.

- Resistant to mechanical damage.

- Available in large diameters for extensive heating systems.

Disadvantages:

- Susceptible to corrosion, especially if not properly maintained.

- Heavier and more challenging to install compared to other materials.

- Requires skilled labor for installation and maintenance.

3. Plastic Pipework

Description: Plastic pipework, including materials such as PB (Polybutylene), PEX (Cross-Linked Polyethylene), and CPVC (Chlorinated Polyvinyl Chloride), is increasingly popular in modern heating systems. These materials offer flexibility and ease of installation.

Applications:

- Domestic heating systems

- Underfloor heating systems

- Low-temperature heating applications

Advantages:

- Lightweight and easy to handle.

- Resistant to corrosion and scale buildup.

- Flexible, allowing for easier installation in tight spaces.

- Generally lower cost compared to metal pipework.

Disadvantages:

- Lower thermal conductivity compared to copper and steel.

- May not be suitable for high-temperature or high-pressure applications.

- Susceptible to UV damage if exposed to sunlight.

4. PEX (Cross-Linked Polyethylene) Pipework

Description: PEX pipework is a type of plastic pipework that has become increasingly popular in both residential and commercial heating systems. PEX pipes are known for their flexibility, durability, and resistance to temperature extremes.

Applications:

- Underfloor heating systems

- Radiant heating systems

- Domestic hot and cold water distribution

Advantages:

- Highly flexible, reducing the need for fittings and joints.

- Resistant to scale and chlorine, extending the lifespan of the system.

- Can handle both high and low temperatures.

- Quick and easy to install with minimal tools.

Disadvantages:

- Not UV-resistant, requiring protection from sunlight.

- Potential for chemical leaching if not certified for potable water use.

May require specialized fittings and tools for installation.

5. CPVC (Chlorinated Polyvinyl Chloride) Pipework

Description: CPVC pipework is a type of plastic pipe that is chemically altered to withstand higher temperatures than standard PVC. It is commonly used in hot water distribution and heating systems.

Applications:

- Domestic hot water systems

- Low-temperature heating systems

- Industrial process piping

Advantages:

- Resistant to corrosion and chemical damage.

- Capable of handling high temperatures up to 200°F (93°C).

- Easy to install using solvent cement, creating strong and leak-free joints.

- Lightweight and cost-effective.

Disadvantages:

- Less flexible compared to PEX, requiring more fittings and joints.

- Not suitable for outdoor use without UV protection.

- Can become brittle with age, especially if exposed to high temperatures for extended periods.

6. Stainless Steel Pipework

Description: Stainless steel pipework is known for its exceptional corrosion resistance, strength, and durability. It is often used in high-end residential and commercial heating systems where longevity and reliability are critical.

Applications:

- High-end residential heating systems

- Commercial and industrial heating applications

- Systems requiring high corrosion resistance

Advantages:

- Exceptional resistance to corrosion and chemical damage.

- Strong and durable, suitable for high-pressure applications.

- Long lifespan with minimal maintenance.

- Aesthetic appeal for exposed installations.

Disadvantages:

- Higher cost compared to other materials.

- Requires specialized tools and skills for installation.

- Less flexible, making installation more challenging in tight spaces.

7. Aluminium Pipework

Description: Aluminium pipework is lightweight and has good thermal conductivity, making it suitable for certain heating applications. It is often used in combination with other materials to enhance system performance.

Applications:

- Underfloor heating systems

- Low-temperature heating applications

- Systems where weight reduction is important

Advantages:

- Lightweight, reducing the load on supporting structures.

- Good thermal conductivity for efficient heat transfer.

- Resistant to corrosion and chemical damage.

- Easy to install and handle.

Disadvantages:

- Lower strength compared to steel and copper, limiting its use in high-pressure applications.

- Potential for galvanic corrosion if in contact with dissimilar metals.

May require protective coatings to prevent oxidation.

Conclusion

Understanding the different types of heating pipework is essential for designing and maintaining efficient and reliable heating systems. Copper, steel, plastic, PEX, CPVC, stainless steel, and aluminium pipework each offer unique advantages and are suitable for various applications. By carefully considering the specific requirements of your heating system, installation conditions, budget, and long-term maintenance needs, you can select the most appropriate pipe material to ensure optimal performance and longevity.

Whether you are planning a new installation or upgrading an existing system, choosing the right heating pipework is a critical decision that can significantly impact the efficiency, durability, and overall success of your heating system.